Understanding the Different Types of Local Exhaust Ventilation

In industrial environments where airborne contaminants pose a risk to workers' health and safety, local exhaust ventilation (LEV) systems are essential. They effectively control and minimise exposure to dust, fumes, vapours, and other hazardous substances. At WBT Services Ltd, we specialise in a range of LEV systems suitable for various industries across the UK. In this article, we'll explore the different types of Local Exhaust Ventilation systems and how they contribute to creating a safer and healthier workplace.

What is Local Exhaust Ventilation?

Local Exhaust Ventilation (LEV) is an engineering control system designed to reduce the exposure to airborne contaminants in the workplace. LEV systems capture contaminants at their source, preventing them from dispersing into the work environment. This is crucial for compliance with health and safety regulations and maintaining a productive workforce.

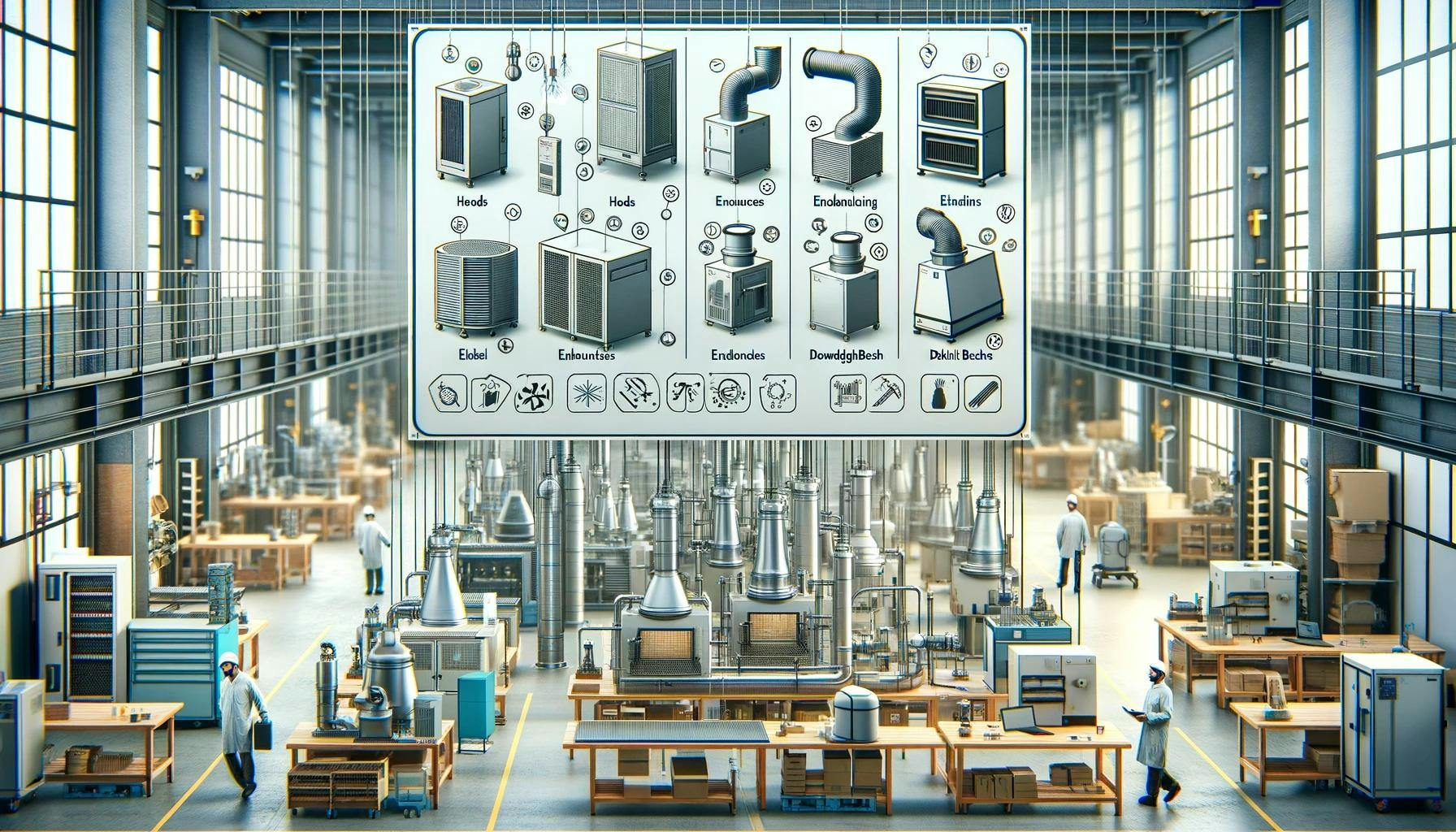

1. Captor Hoods

Captor hoods are one of the most common types of LEV systems. They are designed to enclose the source of the contaminant as much as possible without hindering the task at hand. They generally work well for fixed processes where the operation generates emissions in a predictable and contained area. The challenge lies in designing a hood that offers sufficient capture velocity to draw in the contaminants without being overly disruptive to the workflow.

2. On-Tool Extraction Systems

On-tool extraction is another variety of LEV and is particularly effective for hand-held operations, such as grinding, sanding, or cutting. These systems are directly connected to the tool and capture pollutants as they are generated, providing highly focused extraction. On-tool extraction is beneficial when the contaminant source is highly mobile or when workspaces are constrained.

3. Canopy Hoods

Canopy hoods are a form of LEV that does not enclose the source but rather hangs over like an umbrella. This type of hood is often used above tanks or vats where harmful gases may rise. While canopy hoods are not as effective at capturing and controlling contaminants as other methods, they can be appropriate for certain operations, particularly when it's impractical to use a closer capture method.

4. Downdraught Benches

Downdraught benches are specialised work surfaces that incorporate LEV directly into the bench design. These are ideally suited for operations where work is done on small parts, or detailed assembly work is required. The downdraught bench pulls contaminants downwards, away from the worker's breathing zone, and is an effective form of LEV for fine dusts and smaller workpieces.

5. Booths and Enclosures

These are more extensive versions of local exhaust systems. They are designed to contain the work process within an enclosure or booth, with fresh air drawn in a controlled manner to ensure that no contaminants escape into the broader work environment. This type of LEV can be highly effective but requires careful design to ensure workers inside the booth have adequate breathable air.

6. Receiving Hoods

Receiving hoods, although not capturing contaminants at the source, are designed to trap pollutants at the point they are emitted into the air. They are generally suited for non-industrial settings where the containment of odour or less harmful contaminants is essential.

Each of these different types of Local Exhaust Ventilation systems has its specific applications, advantages, and considerations for implementation. The key to effective LEV design is understanding the processes and workplace environment to select and tailor the correct system. Factors such as the type and amount of contaminant, process requirements, worker mobility, and space constraints all impact ventilation system design.

Regulatory Compliance and Performance Assessment

LEV systems are not merely about installation but require regular testing and maintenance to ensure they continue to perform effectively. In the UK, the Control of Substances Hazardous to Health (COSHH) Regulations demand that all LEV systems be thoroughly examined and tested at least once every 14 months. At WBT Services Ltd, we understand the importance of compliance and provide comprehensive inspection and maintenance services to ensure your LEV systems meet all regulatory requirements.

Conclusion

Investing in the right type of Local Exhaust Ventilation is critical for safeguarding employees against harmful airborne contaminants. With the various LEV options available, selecting an appropriate system tailored to your workplace needs will substantially reduce health risks and enhance worker productivity.

It's not just about having any system in place; it's about having the right system that is compliant, efficient, and effective within your specific industrial environment. That's why it is crucial to collaborate with an experienced solutions provider like WBT Services Ltd, which offers in-depth knowledge and tailored services across the UK to help businesses maintain a safe work environment. For more details on our services and how we can assist your business with LEV systems, please visit WBT Services Ltd.

In the realm of workplace safety, the stakes are undeniably high. The different types of Local Exhaust Ventilation available represent a critical component in the ongoing effort to ensure the well-being of workers in various industrial settings. By capturing and extracting harmful emissions at the source, businesses can not only comply with health and safety regulations but also demonstrate a robust commitment to their most valuable asset – their employees.