Dilution Ventilation vs Local Exhaust Ventilation: Choosing the Right System

In the realm of industrial health and safety, effective workplace ventilation is paramount. It not only preserves the integrity of the work environment but also safeguards the wellbeing of the employees. Two primary methods for managing airborne contaminants in industrial settings are dilution ventilation and local exhaust ventilation. Making an informed choice between dilution ventilation vs local exhaust ventilation is crucial for any facility operator.

Understanding Dilution Ventilation

Dilution ventilation, also known as general ventilation, operates on the principle of dispersing contaminants within the air to reduce the overall concentration. Rather than targeting a specific source of pollution, dilution ventilation works to circulate fresh air throughout the entire space. Air is introduced from the outside and, with the aid of fans and ducts, mixed with the indoor air, thereby diluting the concentration of harmful substances.

The primary objective of dilution ventilation is to maintain air quality across the entire work area by ensuring that there is a constant supply of fresh air. This method can be effective for managing low toxicity substances where source concentrations are not excessively high.

Pros of Dilution Ventilation

- Simple to design and install

- Provides uniform ventilation throughout the space

- Less complex to maintain compared to other systems

- Suitable for low hazard levels

Cons of Dilution Ventilation

- Not efficient for highly toxic or concentrated contaminants

- Requires a significant volume of clean outside air

- Less effective where pollutants are produced at high rates

The Local Exhaust Ventilation Approach

Local exhaust ventilation (LEV) systems take a more direct approach to controlling contaminants, targeting emissions at their source before they spread into the workplace environment. These systems consist of capture hoods, ducting, an air cleaner (if necessary), and an exhaust fan, all designed to draw hazardous substances away from workers' breathing zones.

The efficacy of LEVs lies in their ability to prevent pollutants from dispersing into the air, making them particularly suitable for dealing with high risk or potent sources of contamination. As such, LEVs are often used when dealing with substances such as fumes from welding, chemicals in pharmaceutical manufacturing, or dust from woodworking operations.

Pros of Local Exhaust Ventilation

- Highly effective at controlling contaminant dispersion

- Reduced overall airflow requirement, hence energy savings

- Tailored to specific emission sources

- Can handle high-hazard or high-concentration contaminants

Cons of Local Exhaust Ventilation

- Typically more complex and expensive to design, install, and maintain

- Can be less flexible if production processes change

- Requires careful positioning to be effective

Dilution Ventilation vs Local Exhaust Ventilation: The Decision Process

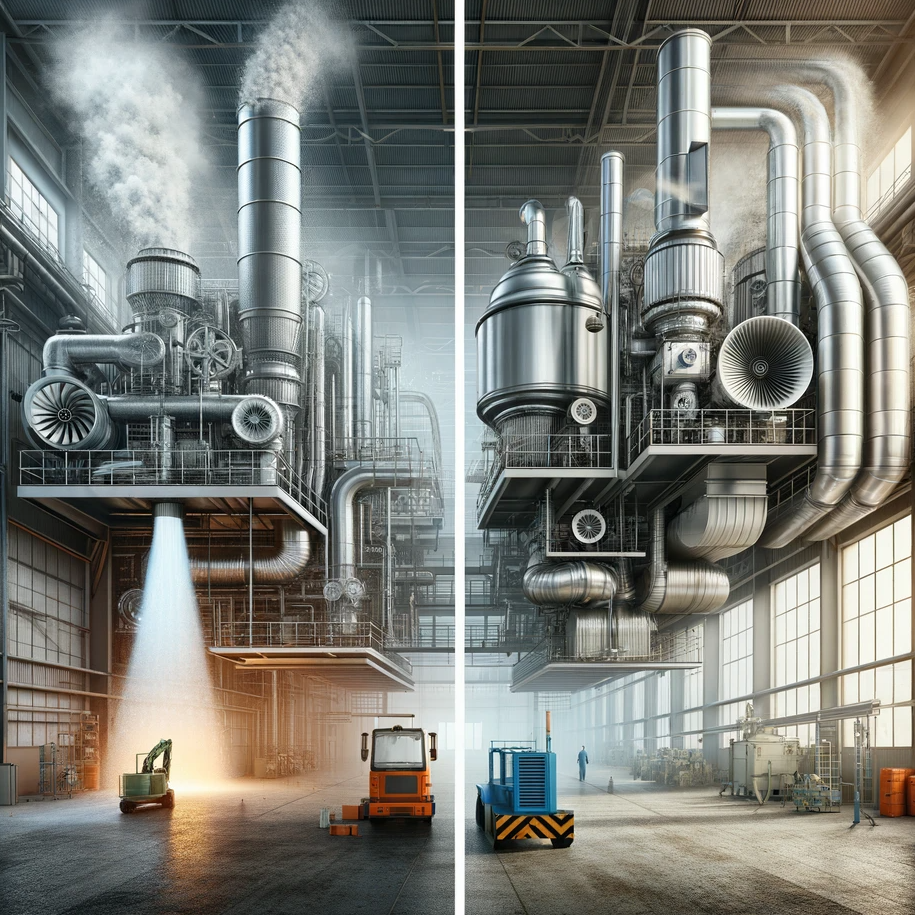

When contemplating dilution ventilation vs local exhaust ventilation, several factors should be considered, including the nature of the contaminants, regulatory requirements, and the layout of the facility. Local exhaust ventilation tends to be the preferable choice for industries dealing with high-risk pollutants, as it offers a more targeted control method. Conversely, dilution ventilation may suffice in scenarios where contaminants are relatively low in toxicity and produced in lesser volumes.

Another important factor is cost - both initial investment and ongoing expenses. While local exhaust systems might require a higher upfront cost due to their complexity, they can be more cost-effective in the long run, especially in terms of operational expenses as they often require moving less air, potentially resulting in lower energy costs.

Moreover, compliance with health and safety regulations is crucial. In many jurisdictions, including the UK, there are stringent guidelines and statutory requirements for workplace exposure limits to hazardous substances. As such, the system chosen must be robust enough to ensure these limits are not exceeded.

In making the choice between dilution ventilation and local exhaust ventilation, a comprehensive risk assessment should be undertaken to determine the most effective method for controlling air quality. This assessment typically includes:

- Identifying the nature and amount of the contaminants

- Understanding the potential health risks associated with exposure

- Evaluating the effectiveness of varying ventilation strategies

- Considering the layout and processes within the facility

Conclusion

In the debate between dilution ventilation vs local exhaust ventilation, there is no one-size-fits-all solution. The decision should be made based on a meticulous evaluation of the specific requirements of a given industrial setting.

For organisations operating across the UK such as WBT Services Ltd, with an unwavering commitment to industrial solutions, ensuring that the right ventilation system is in place is a fundamental aspect of their service. These systems are not merely about compliance; they are about the well-being of employees and efficiency of operations.

When examining your ventilation needs, it is advisable to consult with experienced professionals who can provide bespoke assessments and solutions tailored to your unique situation. For more information and assistance with your ventilation requirements, visit WBT Services Ltd.

Ultimately, whether you opt for dilution ventilation or local exhaust ventilation, the goal remains the same: maintaining a safe and healthy work environment for all.