The Essential Local Exhaust Ventilation Inspection Checklist

Ensuring a safe and healthy work environment is paramount across various industries in the UK. A critical aspect of this commitment is the steadfast maintenance and inspection of local exhaust ventilation (LEV) systems designed to control the release of harmful substances into the workplace air. Routine inspections are not just a regulatory requirement but also a fundamental practice to prevent occupational diseases and protect employees from exposure to hazardous substances. In this light, it is essential to understand and implement a comprehensive local exhaust ventilation inspection checklist.

Local exhaust ventilation systems are bespoke solutions engineered to capture and remove contaminants at the source, before they enter the breathing zone of workers. But as is typical with any engineered system, regular inspections and maintenance are critical to ensure proper functioning. To stay abreast of your LEV systems, here's a definitive local exhaust ventilation inspection checklist to guide you through your inspections.

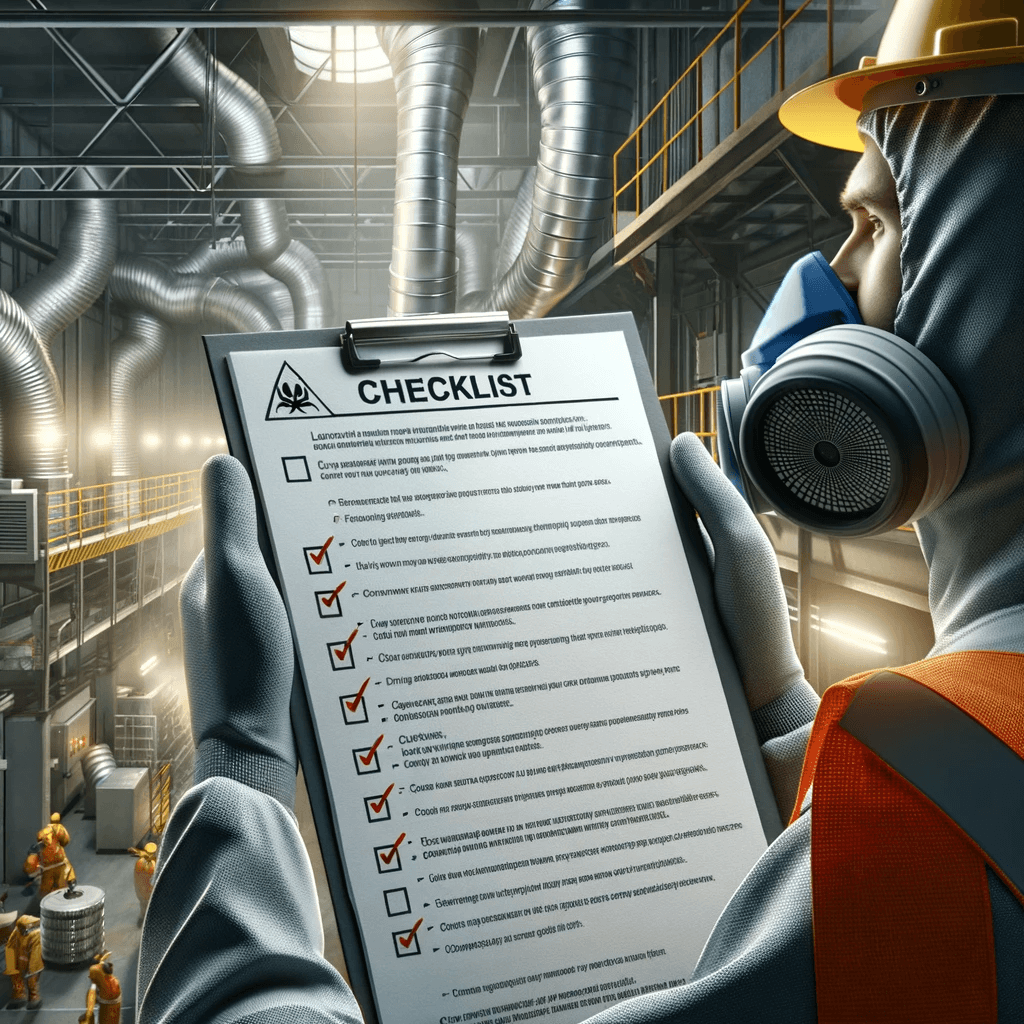

Visual Inspection

1. Hood Condition: Check the condition of the LEV hood for any damage, signs of wear, or corrosion. Ensure that the hood is positioned correctly to effectively capture emissions.

2. Ductwork: Inspect the ductwork for any leaks, blockages, or signs of corrosion. Verify that air flows smoothly without any obstructions.

3. Airflow Indicators: Confirm that airflow indicators, where fitted, are operational and clearly showing the system's performance status.

4. Filters: Check the condition of any filters for clogging or damage. Replace if necessary according to the manufacturer’s specifications.

Performance Testing

5. Air Velocity: Verify that the air velocity at the hood face or within the duct complies with relevant design specifications. Use an anemometer for accurate measurement.

6. Airflow Volume: Confirm that the volume of air being extracted meets the system's designed parameters. This ensures the LEV is capturing and containing contaminants effectively.

7. Static Pressure: Measure the static pressure within the system. This will indicate whether the LEV is operating under the designed pressure conditions.

System Components

8. Fans: Inspect fans for signs of damage or wear. Ensure that they are secure and free from excessive vibration.

9. Noise and Vibration: Check for any unusual noise or vibration, which could indicate mechanical issues with the system's components.

10. Dampers: Make sure that any dampers present are operational and correctly adjusted to maintain proper airflow through the system.

Cleanliness

11. Internals: Inspect the inside of the ductwork and hoods to ensure they are clean and free from any dust build-up or deposits.

12. External Surface: Check the cleanliness of the external surface of the LEV system, and remove any accumulated dirt or grease.

Control Measures

13. Warning Signs: Ensure that all necessary warning signs and labels are present, legible, and conform to regulatory requirements.

14. Operating Procedures: Confirm that up-to-date operating procedures are available and accessible to workers who operate or maintain the LEV system.

Record Keeping

15. Documentation: Maintain a record of all inspection findings, including dates, identifying any defects or maintenance actions taken.

16. Logbooks: Keep a logbook with a detailed account of the system's maintenance history and any repairs or adjustments made.

Conclusion of Inspection

17. Summary Evaluation: At the end of the inspection, provide a summary evaluation of the state of the LEV system. This should include any recommendations for immediate or scheduled repairs, replacements, or improvements.

By following this local exhaust ventilation inspection checklist, employers can preserve the integrity of their LEV systems and ensure continuous protection of their workforce from hazardous airborne substances. It is recommended that inspections are carried out by competent personnel who are well-acquainted with the intricacies of LEV systems. For organisations within the UK looking for expertise in this domain, WBT Services Ltd offers professional industrial system solutions, including the inspection and maintenance of local exhaust ventilation systems.

Regular and thorough inspections are not just compliance with the Control of Substances Hazardous to Health (COSHH) Regulations but are also integral to a company's operational efficiency and sustainability. An effective local exhaust ventilation inspection checklist can serve as the roadmap towards maintaining a safe working environment, protecting the well-being of employees, and ensuring compliance with health and safety regulations. This proactive practice aligns with the ethos of care and excellence, hallmarks of a responsible and forward-thinking organisation.

In conclusion, incorporating a meticulous local exhaust ventilation inspection checklist into the regular workflow is a critical aspect of ensuring the health and safety of the workplace. Ensure that the professionals conducting the inspections have the needed expertise and remember that the health of your workforce and the robustness of your operations depend significantly on the reliability of your LEV systems. For more extensive support on the inspection and maintenance of your local exhaust ventilation systems across the UK, consider reaching out to an experienced service provider like WBT Services Ltd.