The Imperative of Regular Local Exhaust Ventilation Maintenance

Any workplace that introduces hazardous airborne contaminants into the environment must utilise effective control measures to protect the health of workers and comply with health and safety regulations. Within the vast landscape of industrial systems, local exhaust ventilation (LEV) systems play a crucial role in maintaining clean air standards by capturing contaminants directly at the source and safely expelling them away from working areas. To sustain their protective functions and ensure ongoing adherence to legal requirements, local exhaust ventilation maintenance is an unequivocal necessity. WBT Services Ltd, operating across the UK, emphasises the importance of rigorously maintaining these systems to ensure optimal performance and workplace safety.

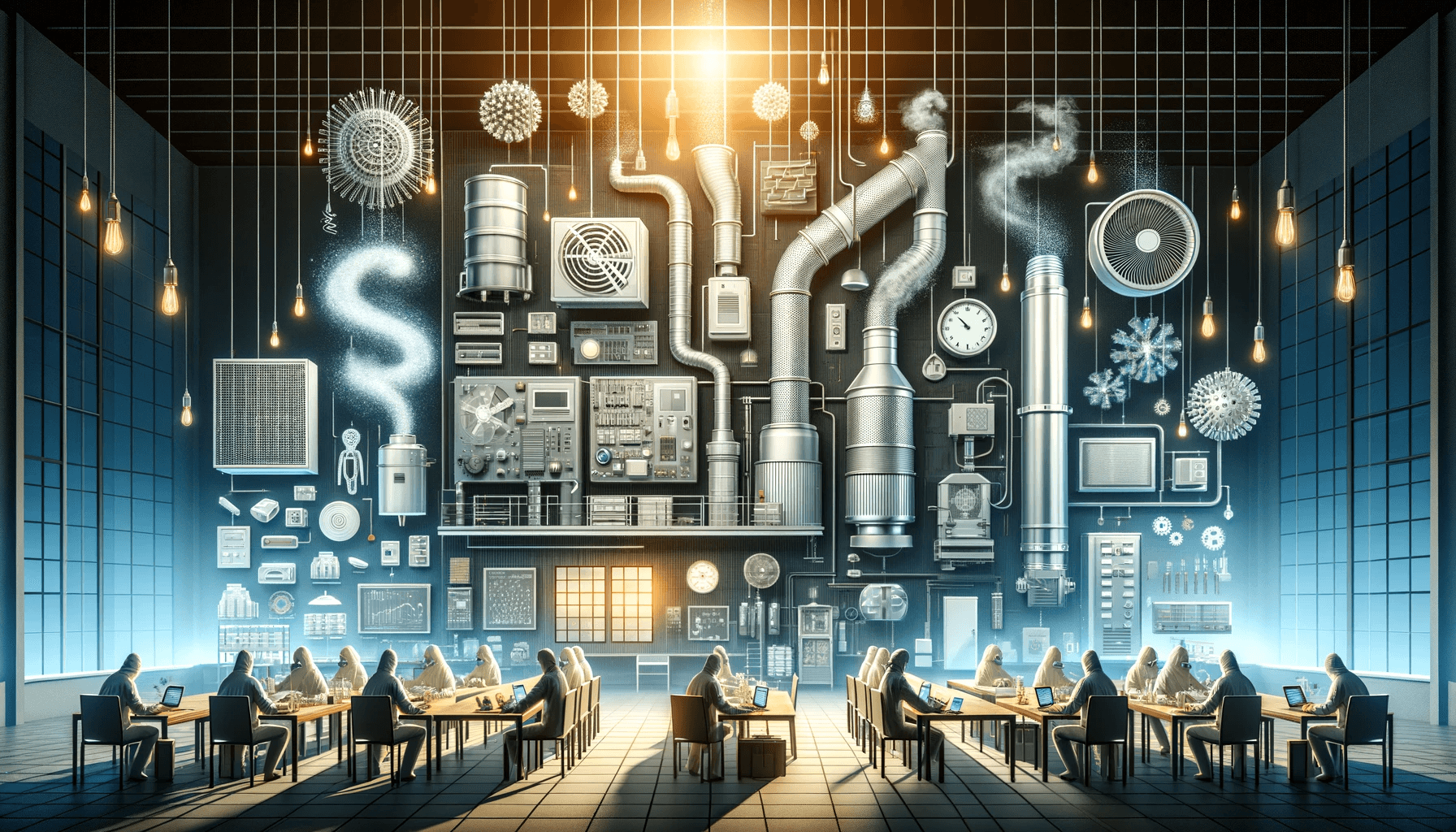

Understanding Local Exhaust Ventilation Systems

Before delving into the maintenance aspect, it is vital to understand what local exhaust ventilation systems are designed to do. These are engineering controls that reduce exposure to airborne contaminants such as dust, fumes, vapours, and gases in the workplace. They work by capturing these pollutants at their source before they can disseminate into the worker's breathing zone.

An effective LEV system comprises several components, including a hood to capture the contaminant, ducting to transport the captured substances, an air cleaning device to remove contaminants from the airflow, and a fan to move air through the system. Regular inspection and maintenance are critical in ensuring that each component operates effectively to reduce exposure to hazardous substances.

The Importance of Local Exhaust Ventilation Maintenance

Local exhaust ventilation maintenance is not just a recommendation; it is codified within the UK's health and safety laws. The Control of Substances Hazardous to Health (COSHH) Regulations mandates that employers must adequately control the release of hazardous substances through the appropriate use of LEV systems and ensure these systems are well maintained and thoroughly examined and tested at regular intervals.

Poorly maintained LEV systems can lead to several issues, including reduced efficiency, which may not only cause exposure to harmful contaminants but can also lead to greater energy consumption and higher operating costs. Moreover, blockages or wear and tear can result in system failure, incurring downtime for repairs or replacement, which can be both costly and disruptive to business operations.

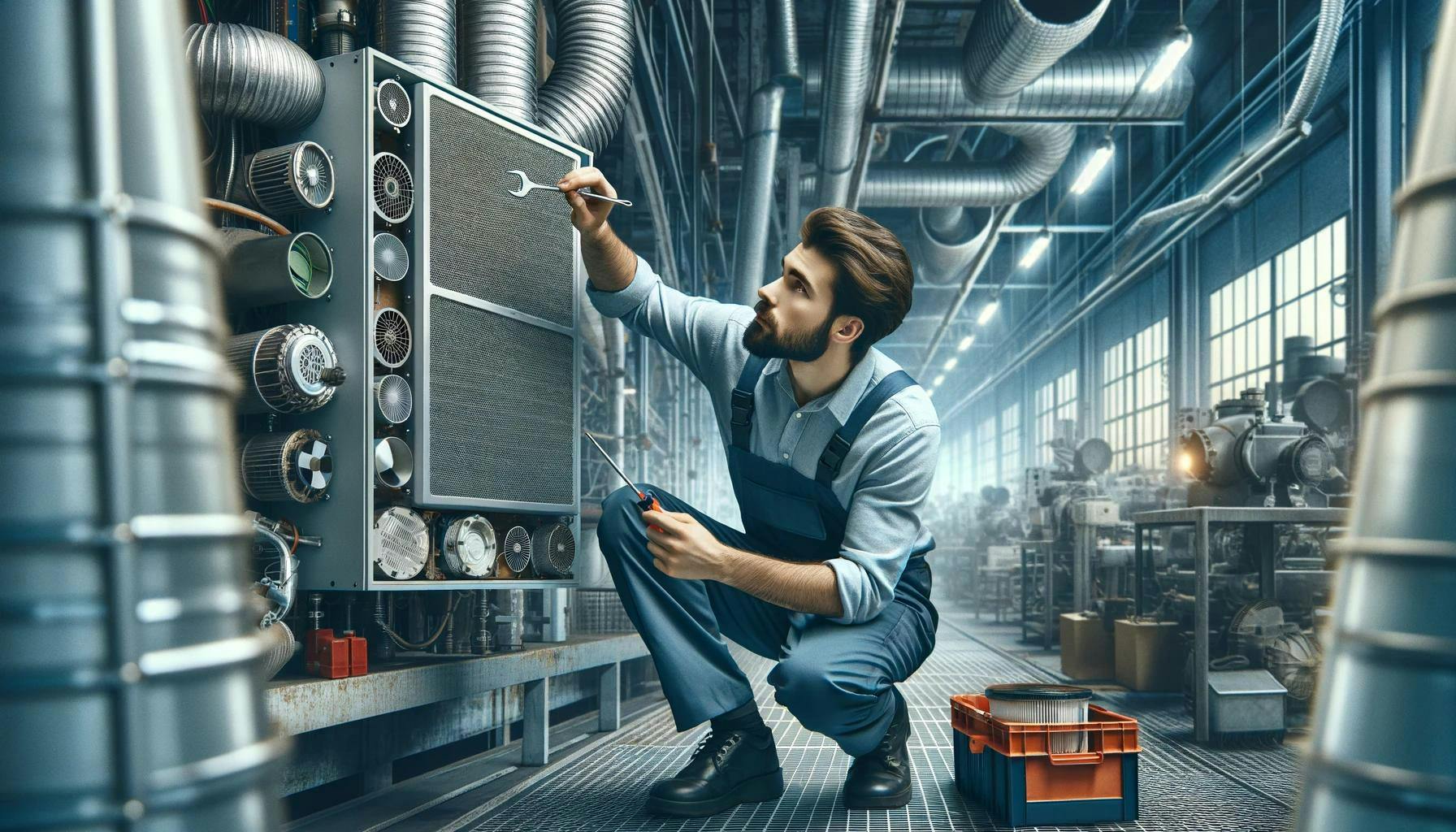

Conducting Local Exhaust Ventilation Maintenance

Local exhaust ventilation maintenance consists of several procedures that extend beyond mere cleaning to include inspection, testing, performance evaluation, and necessary repairs or upgrades. Systematic checks can prevent minor issues from escalating into significant problems that might compromise the safety of the workplace.

Visual Checks: These should be performed regularly to ensure there are no obvious signs of damage or wear to the LEV components.

Cleaning: Ducts, hoods, and air cleaners should be cleaned to prevent buildup, which can reduce system efficiency or become a fire hazard.

Performance Checks: Airflows should be measured and compared against the system’s original performance as specified by the design criteria.

Technical Examination: It involves a more thorough inspection of the LEV system by a competent person. The examination should be charged periodically, typically every 14 months, depending on the operations.

Repair and Replacement: Components that are damaged or worn out should be repaired or replaced promptly to avoid impairing the system's performance.

Record Keeping and Documentation

Detailed records are a key aspect of local exhaust ventilation maintenance. They should include the date of inspections, the name of the inspector, findings, corrective actions taken, and a schedule for the next review. This documentation is not only best practice for maintenance management but also serves as evidence of compliance with health and safety regulations.

Employers should also keep the Local Exhaust Ventilation (LEV) report, which provides documented proof of a system’s compliance with COSHH regulations and outlines any required actions to rectify identified issues.

Choosing a Service Provider for Maintenance

Selecting a competent service provider for local exhaust ventilation maintenance is vital for optimizing system efficiency and maintaining compliance with legal standards. WBT Services Ltd stands as a sterling example of an industrial solutions provider that offers meticulous maintenance services. With an experienced team and comprehensive understanding of the critical nature of LEV systems, WBT Services Ltd delivers maintenance solutions tailored to the specific needs of clients across the UK.

Regular preventive maintenance offered by service providers like WBT Services Ltd, ensures that LEV systems are not only compliant with current health and safety regulations but are also operationally sound, providing a safe working environment.

Conclusion

Local exhaust ventilation maintenance is an integral part of operational safety and legal compliance in any workspace handling hazardous substances. A well-maintained LEV system not only safeguards the health of the workforce but also ensures the longevity of the equipment and the financial bottom line of the business.

WBT Services Ltd — with a reputation for technical expertise and professional service — understands the critical relevance of these systems and is fully equipped to provide comprehensive maintenance services. Meeting the specific needs of workplaces across the UK, WBT Services Ltd is a dependable partner for maintaining local exhaust ventilation integrity and performance.

For further information on LEV maintenance services, visit WBT Services Ltd.