The Future of LEV Design: Innovations and Trends

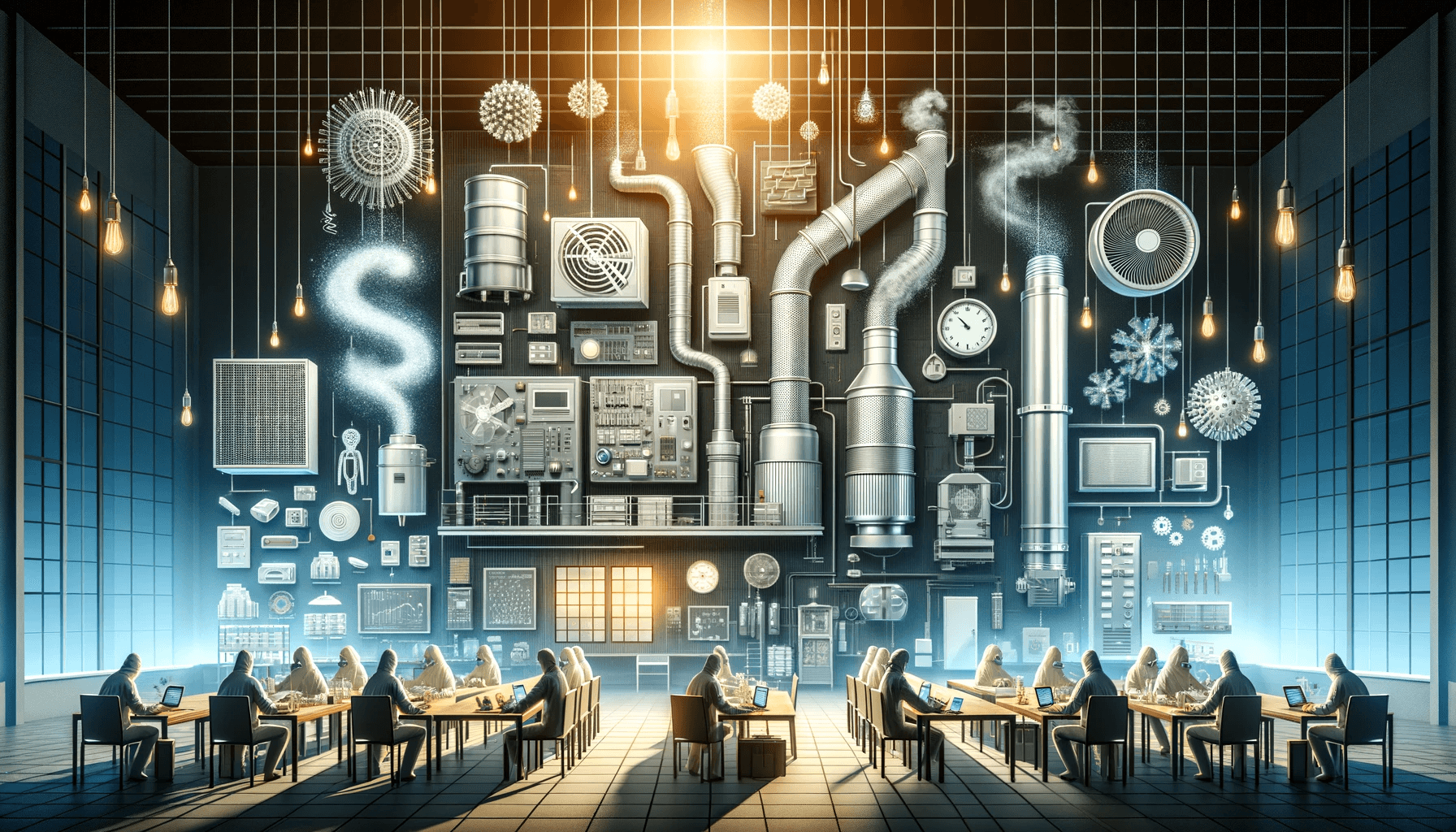

Introduction to LEV Systems

Local Exhaust Ventilation (LEV) systems are crucial in protecting the health of workers by removing airborne contaminants directly at the source. As industries evolve and regulations become more stringent, the future of LEV design is poised for significant advancements. This blog post will explore the emerging innovations and trends that are shaping the LEV landscape, ensuring safer working environments across various sectors.

Technological Advancements in LEV Systems

Technology is at the forefront of LEV innovation, with new designs focusing on energy efficiency, smart monitoring, and compatibility with the Internet of Things (IoT). Let's delve into these developments and how they can benefit your workplace.

Energy-Efficient Designs

One of the primary concerns in LEV systems is the demand for energy. With sustainability being a global priority, new LEV designs are moving towards energy-efficient solutions. This includes the use of EC (Electronically Commutated) motors and optimised airflow designs that minimise resistance and reduce power consumption without compromising performance.

Smart Monitoring Capabilities

Smart sensors and monitoring systems are becoming integral parts of modern LEV design. These systems allow for real-time tracking of air quality and system performance, enabling proactive maintenance and ensuring compliance with health and safety regulations. By incorporating smart technology, you gain the ability to monitor your LEV system's efficiency and detect any issues before they become problematic.

Integration with the Internet of Things (IoT)

The IoT revolution has paved the way for interconnected LEV systems. With IoT integration, LEV systems can communicate with other devices within a facility, providing a comprehensive overview of environmental conditions and facilitating automated responses to changes in air quality or system function.

Regulatory Compliance and Safety

As industry standards evolve, LEV systems must adapt to meet new regulatory requirements. It's not just about adhering to current standards; forward-thinking LEV design anticipates future regulations to ensure long-term compliance and safety.

Adapting to Evolving Standards

Designing LEV systems that can adapt to evolving standards is crucial. This involves modular designs that can be easily upgraded as regulations change, ensuring your system remains compliant without the need for a complete overhaul.

Enhanced Worker Safety

Worker safety is paramount, and the latest LEV designs are increasingly incorporating safety features that go beyond regulatory requirements. This includes failsafe mechanisms and redundancy features that maintain protective measures, even under unexpected conditions.

Tailored Solutions for Diverse Industries

Different industries have unique requirements for LEV systems. Innovative LEV design caters to these needs with customised solutions that address the specific challenges and hazards of each sector.

Customisation for Industry-Specific Challenges

Whether it's managing high-volume dust in woodworking facilities or mitigating chemical vapours in a laboratory, cutting-edge lev design provides tailor-made solutions that ensure optimal protection for every unique scenario.

Expertise in LEV Testing and Maintenance

Alongside design considerations, regular lev testing and maintenance are essential to keep LEV systems at peak performance. Partnering with experts who can offer comprehensive testing and maintenance services is invaluable in maintaining the integrity of your LEV system.

Future Trends to Watch

The horizon of LEV design holds promising trends that will redefine industrial safety. Let's explore what the future might hold.

Adoption of Advanced Materials

New materials are being researched to create more robust and lightweight LEV components. These materials can withstand harsh chemicals and extreme temperatures, enhancing the durability and lifespan of LEV systems.

Increased Focus on User Experience

User experience is taking centre stage in LEV design. Future systems will likely feature more intuitive interfaces and controls, making them easier to operate and maintain, thus reducing the likelihood of user error and increasing overall system effectiveness.

Conclusion

The future of LEV design is bright with technological advancements, a commitment to regulatory compliance and safety, and customisable solutions that meet the specific needs of various industries. By staying informed about these innovations and trends, you can ensure that your workplace remains safe and compliant. For expert guidance on the latest in lev design and to keep your systems at the forefront of industry standards, turn to the professionals who can provide the insights and solutions you need.

Embracing these advancements will not only benefit the health and safety of workers but will also contribute to the efficiency and sustainability of your operations, positioning your business as a leader in workplace safety and innovation.

FAQs

What are the key technological advancements in LEV system design?

Key advancements in LEV design include energy-efficient designs with EC motors and optimized airflow, smart monitoring capabilities with real-time tracking, and integration with the Internet of Things (IoT) for interconnected device communication and automated responses.

How do modern LEV systems ensure compliance with evolving safety regulations?

Modern LEV systems are designed with modularity to easily adapt to changing regulations, thus ensuring long-term compliance. They incorporate advanced safety features such as failsafe mechanisms and redundancy features to maintain protection even in unexpected conditions.

Can LEV systems be customized for different industry requirements?

Yes, LEV systems can be highly customized to meet the specific challenges of diverse industries. Tailor-made solutions are available for scenarios ranging from woodworking dust management to laboratory chemical vapour mitigation, ensuring optimal protection for every unique environment.

Key Takeaways

The future of Local Exhaust Ventilation (LEV) system design is set to greatly enhance workplace safety and efficiency through several key trends and innovations:

Technological Integration and Energy Efficiency: LEV systems are becoming more energy-efficient, integrating technologies such as electronically commutated motors and optimized airflow designs to minimize energy consumption. Smart monitoring capabilities with real-time tracking and Internet of Things (IoT) integration are also emerging, allowing for interconnected systems that automate responses to environmental changes and improve air quality management.

Regulatory Compliance and Enhanced Safety Features: With evolving industry standards, new LEV designs are incorporating modular elements that allow for easy updates to meet future regulations. Advanced systems include failsafe mechanisms and redundancies to ensure continued worker protection, even during unexpected events, thus going beyond current safety requirements.

Customization and Industry-Specific Design: Innovations in LEV design are leading to customized solutions tailored to the unique challenges of different industries. This includes the development of robust materials for durable components, user-friendly interfaces for ease of operation, and access to expert maintenance services to ensure optimal functionality and compliance with industry-specific requirements.

Adopting these advancements in LEV design not only protects worker health but also increases operational sustainability and positions businesses as leaders in workplace safety and innovation.