What is the Purpose of Local Exhaust Ventilation?

In the vast expanse of industrial environments where hazardous substances and unfavourable conditions are a norm, maintaining air quality is of paramount importance. This essential aspect of occupational safety is facilitated by local exhaust ventilation (LEV) systems – an engineering control measure designed to reduce employee exposure to airborne contaminants. Understanding the purpose of local exhaust ventilation is a cornerstone for fostering a safe, compliant, and healthful workplace, particularly in the backdrop of regulations and standards that govern occupational health and safety in the UK.

Understanding Local Exhaust Ventilation

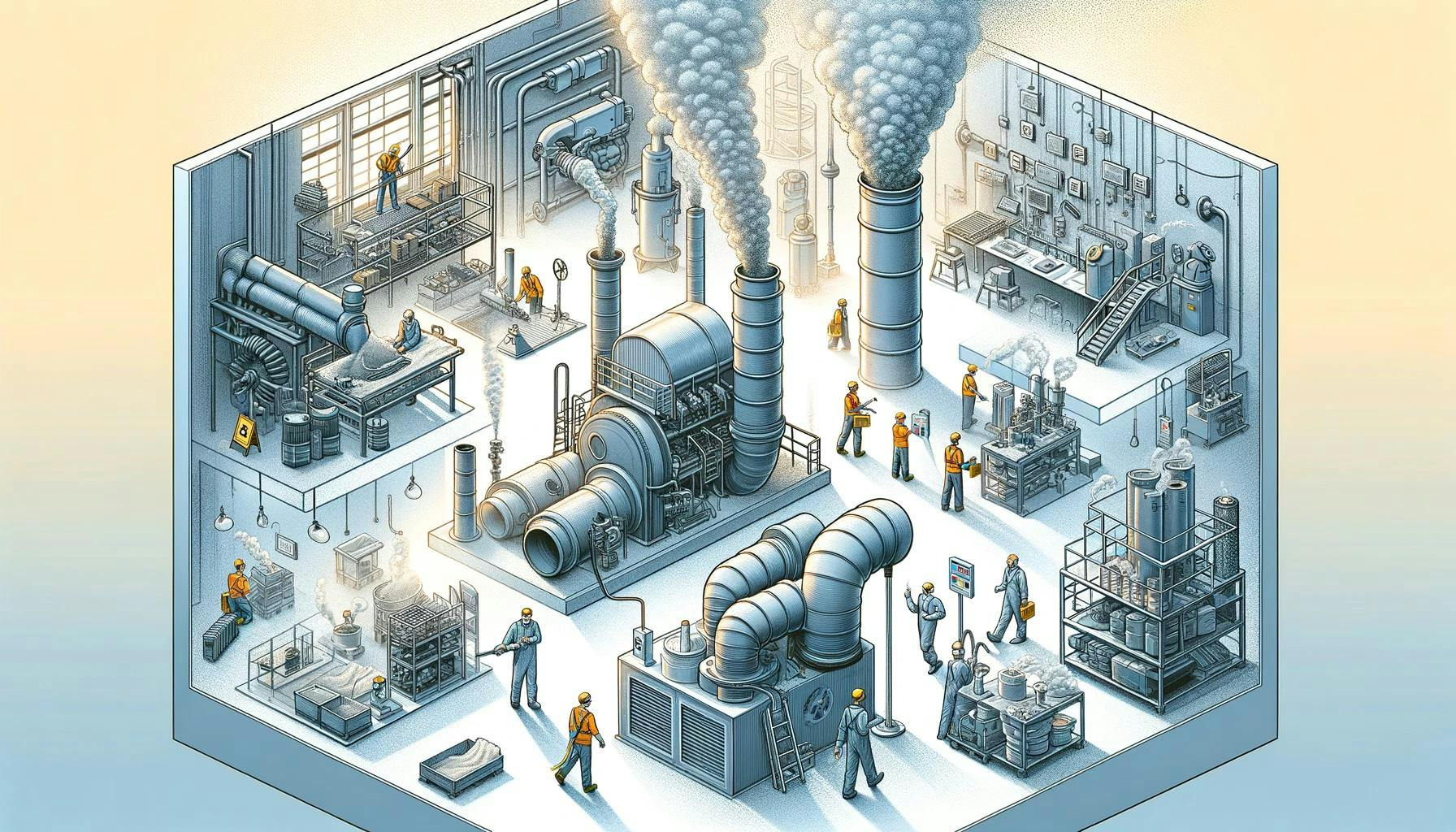

Local exhaust ventilation is a ventilation system that captures airborne contaminants such as dust, fumes, and vapours at their source of generation and expels them outside of the working environment. By doing so, it prevents the distribution and inhalation of these contaminants, protecting workers' health and contributing to a safer workspace.

The purpose of local exhaust ventilation is multifaceted. It is not only an instrument for meeting legal obligations under the Health and Safety at Work etc. Act 1974 and the Control of Substances Hazardous to Health Regulations 2002 (COSHH), but it also plays a critical role in:

Protecting Health and Enhancing Safety

The primary purpose of local exhaust ventilation is to protect the respiratory health and overall well-being of workers. Industries that have robust LEV systems in place significantly reduce the risk associated with breathing in harmful particles. By capturing contaminants at the point of emission, local exhaust ventilation ensures that they do not become part of the breathing zone of employees, thus preventing occupational illnesses and diseases such as asthma, dermatitis, and even certain types of cancer.

Complying with Occupational Health Standards

Local exhaust ventilation is vital for compliance with occupational health and safety standards. It forms an integral part of a business's responsibility to ensure a safe work environment as stipulated by various regulations. Employers are legally bound to control exposure to hazardous substances and to ensure that exposure is either prevented or, where that is not reasonably practicable, adequately controlled.

Increasing Operational Efficiency

Beyond maintaining health and safety, local exhaust ventilation aids in enhancing the efficiency of industrial processes. By removing airborne contaminants, the clarity of the work area increases, thus improving visibility and accuracy in operations that require detailed attention. This removal of pollutants can also reduce the frequency of machine maintenance and cleaning, as the build-up of debris is minimally allowed.

Conserving Energy and Maintaining Air Quality

Highly effective local exhaust ventilation systems are designed to target only the areas that release contaminants. This focus on source capture means that less energy is expended in maintaining clean air across the entire workspace. Moreover, these systems contribute to environmental protection efforts by ensuring that hazardous emissions are filtered and cleaned before being discharged into the atmosphere.

The significance of local exhaust ventilation cannot be overstated. It is a combination of health preserver, regulatory compliance tool, efficiency booster, and environmental protector. Consequently, it is imperative for industries to not just install local exhaust ventilation systems, but to regularly maintain and test them to ensure they continue to fulfil their purpose effectively.

Implementation and Maintenance

Implementing LEV systems requires meticulous planning where the design is tailored to the specific needs of the industrial processes. The configuration involves consideration of capture hoods, ducting, air cleaners, and fans. Once installed, regular examinations and testing of the LEV systems, also known as thorough examination and testing (TExT), are mandatory. These tests, carried out at least every 14 months, ensure the systems are in good working order, offering peace of mind that the air quality in the facility remains within safe limits.

The Commitment of WBT Services Ltd

With a steadfast commitment to health and safety, companies like WBT Services Ltd offer expertise in the design, installation, and maintenance of local exhaust ventilation systems across the UK. Their understanding of the diverse needs of various industries positions them as a leading provider of tailor-made industrial systems and solutions. Their pledge to uphold the highest standards of environmental control is reflected in every aspect of their service delivery. For more information about their offerings, visit WBT Services Ltd.

Conclusion

The purpose of local exhaust ventilation is pivotal to maintaining a healthy and productive workplace. It is a sophisticated interplay of employee well-being, legal compliance, operational proficiency, and environmental stewardship. Smart and efficient LEV systems hold the key to achieving an environmentally responsible and regulatory compliant industrial atmosphere. For this reason, embracing the expertise of seasoned professionals in the field becomes not just advisable, but a fundamental business strategy for industries that prioritize the health and safety of their workforce and the cleanliness of their operations.

By incorporating a robust approach to local exhaust ventilation, industries can look forward to a future where occupational health hazards are not just managed but proactively controlled. Such a future ensures a committed workforce, a cleaner environment, and a sustainable business model, ultimately contributing to the holistic growth and success of the industry at large.