When Should Local Exhaust Ventilation Be Used?

In the industrial realm, maintaining a safe and healthy work environment is paramount. One of the most effective ways to control airborne contaminants is through an efficient local exhaust ventilation (LEV) system. For businesses across the UK, including those served by WBT Services Ltd, understanding when to implement LEV can be critical to safeguarding the health of employees and ensuring compliance with health and safety regulations. Here, we explore the scenarios that necessitate the use of local exhaust ventilation systems.

What is Local Exhaust Ventilation?

Before diving into the specifics, it is crucial to define when local exhaust ventilation should be used. LEV systems are designed to capture and remove airborne contaminants at the source, preventing them from spreading into the workplace environment. These systems typically comprise an extraction hood, ducting, an air cleaner, and a fan, collectively working to extract hazardous substances such as dust, vapour, and fumes, before they become inhaled by workers.

When to Use Local Exhaust Ventilation

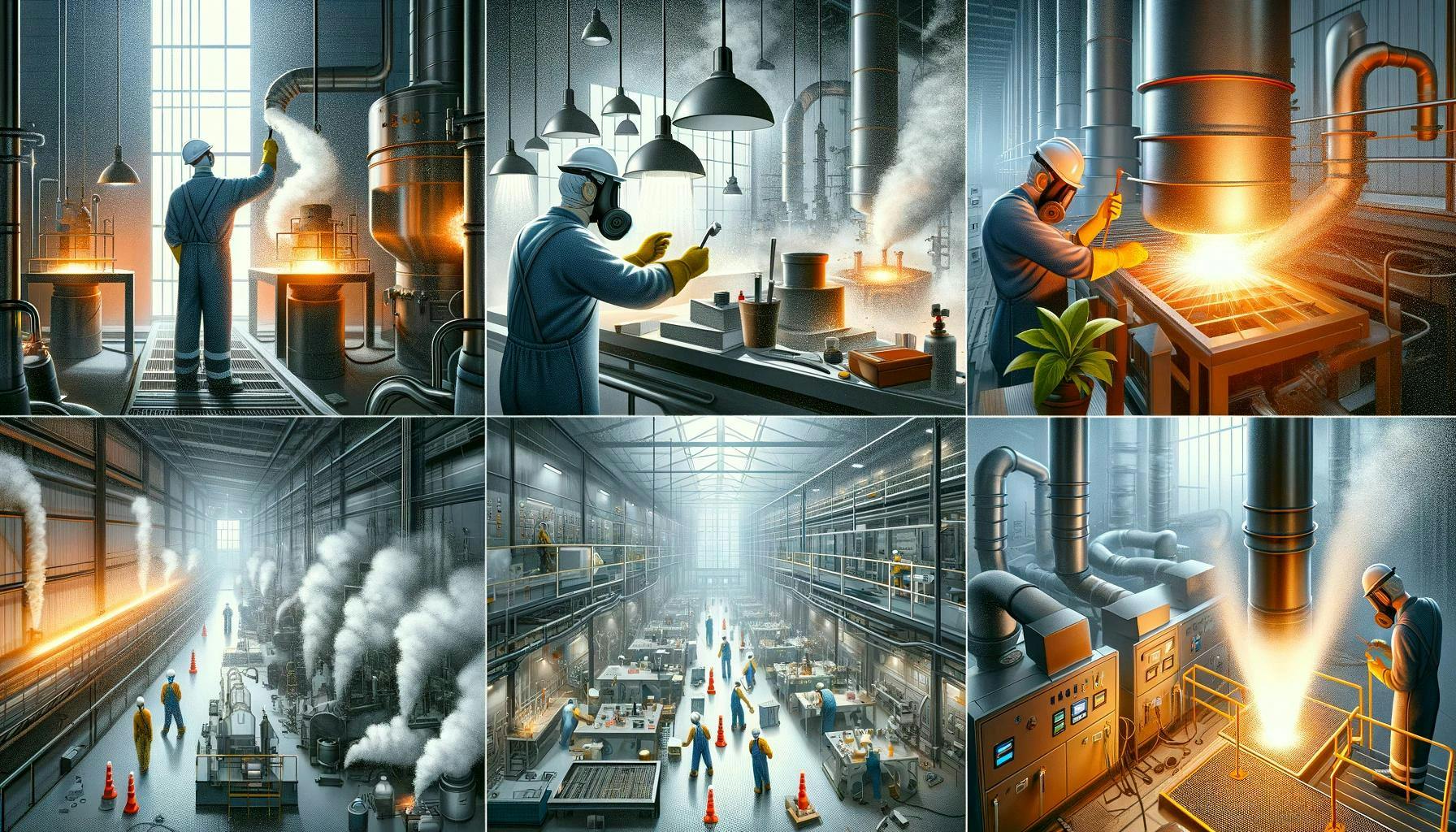

High-Risk Environments

The primary scenario for deploying local exhaust ventilation is in environments where there is the production of hazardous airborne pollutants. This includes industries such as manufacturing, woodworking, pharmaceuticals, automotive and chemical processing, where the operations involve cutting, grinding, spraying, or handling of potentially toxic materials.

Compliance with Occupational Health Standards

The regulatory landscape in the UK dictates stringent health and safety standards in workplaces, including the Control of Substances Hazardous to Health (COSHH) regulations. As part of compliance, LEV systems may be required to control exposure to harmful contaminants. Businesses must assess risks and implement appropriate control measures, with LEV being the preferred route when engineering controls are needed to reduce exposure to below workplace exposure limits (WELs). The regulation also requires LEV systems to be tested regularly.

Inadequacy of General Ventilation

General ventilation, while helpful in some cases, might not suffice when it comes to controlling more concentrated pollutants. When should local exhaust ventilation be used in place of general ventilation? The answer lies in the spatial consideration and the nature of the contaminants. LEV systems are specifically designed for confined spaces or situations where general ventilation cannot effectively reduce contamination to acceptable levels, ensuring targeted and efficient contaminant removal.

Processes with High Heat Generation

Processes that generate significant amounts of heat, such as welding, smelting, or foundry work, require constant monitoring and control of emissions. LEV systems are not only useful for removing harmful particulate matter but also for protecting workers from excessive heat exposure and potential heat-induced health problems.

Reducing the Risk of Fire and Explosion

Certain industrial processes can produce explosive or flammable vapours. In such instances, the use of LEV is critical to minimise the concentration of these dangerous substances to levels that are below their lower explosive limit, thereby reducing the likelihood of fire or explosion within the work area.

For Specific Contaminants with Known Health Impacts

Some industries deal with specific substances that are known to have direct negative health impacts, such as silica dust, isocyanates, or asbestos fibres. LEV systems are crucial for these scenarios to ensure that such contaminants are safely removed and workers are not exposed to health risks.

Implementing Ergonomic Workplace Designs

LEV systems can also contribute to a more ergonomic workplace design. By reducing the ambient levels of hazardous substances, workers can operate in a cleaner environment, potentially reducing the need for personal protective equipment (PPE), which can sometimes be cumbersome or restrictive.

How Can WBT Services Ltd Help?

WBT Services Ltd offers tailored solutions for businesses across the UK in need of local exhaust ventilation systems. Their expertise ensures not only the implementation of effective LEV strategies but also compliance with health and safety regulations.

For more insight into their services, visit WBT Services Ltd where you can find information regarding the design, installation, and maintenance of LEV systems suitable for various industrial applications.

Conclusion

Understanding when local exhaust ventilation should be used is pivotal for industrial enterprises. LEV systems are a fundamental component of health and safety management where there is a presence of harmful airborne contaminants. Strategic implementation of LEV is mandated in certain high-risk environments, for regulatory compliance, in areas where general ventilation does not suffice, during high heat processes, where there’s a risk of fire and explosion, when handling known toxic substances, and within ergonomic workplace designs. Employers have the responsibility to determine the suitability of LEV systems within their operations and to take the necessary steps to protect their workforce.

The commitment to occupational health and safety is one that businesses like WBT Services Ltd understand and support unwaveringly. As industries evolve and regulations become increasingly specific, the role of local exhaust ventilation remains a steadfast element in the pursuit of a cleaner, safer, and more compliant workplace.